Our accelerator for more efficiency

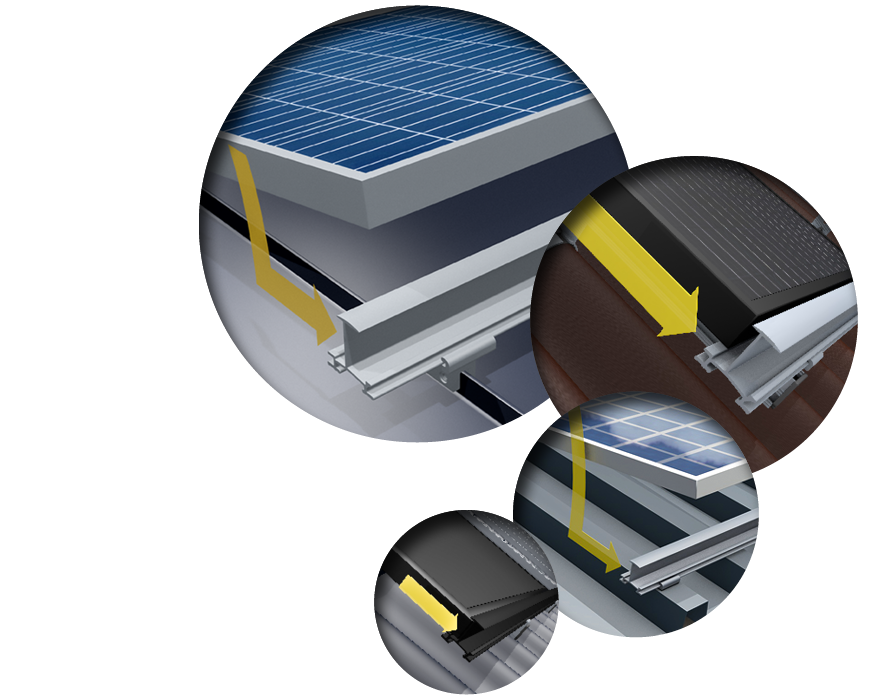

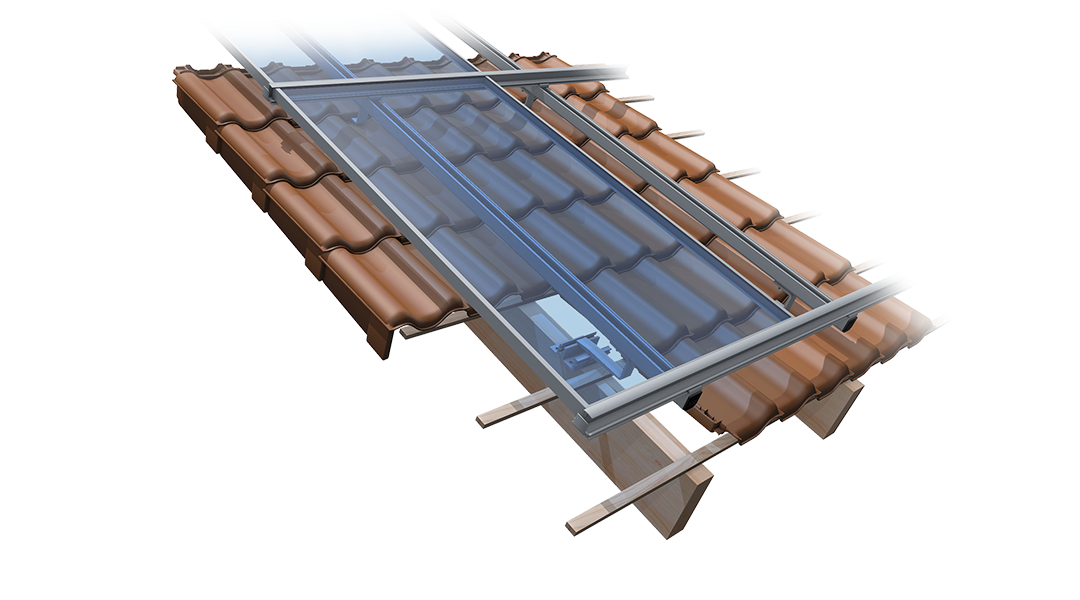

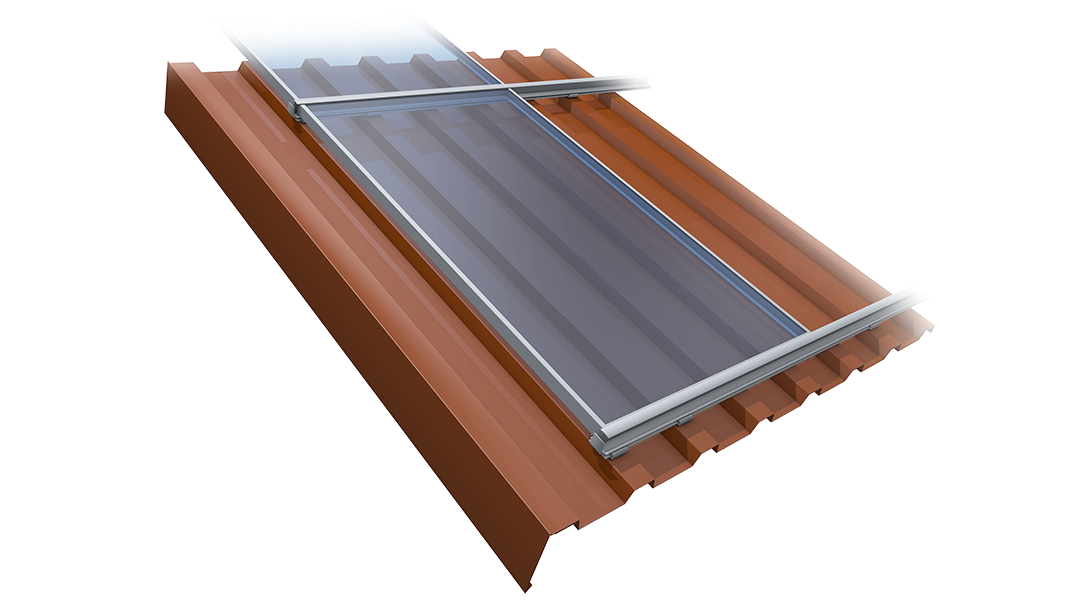

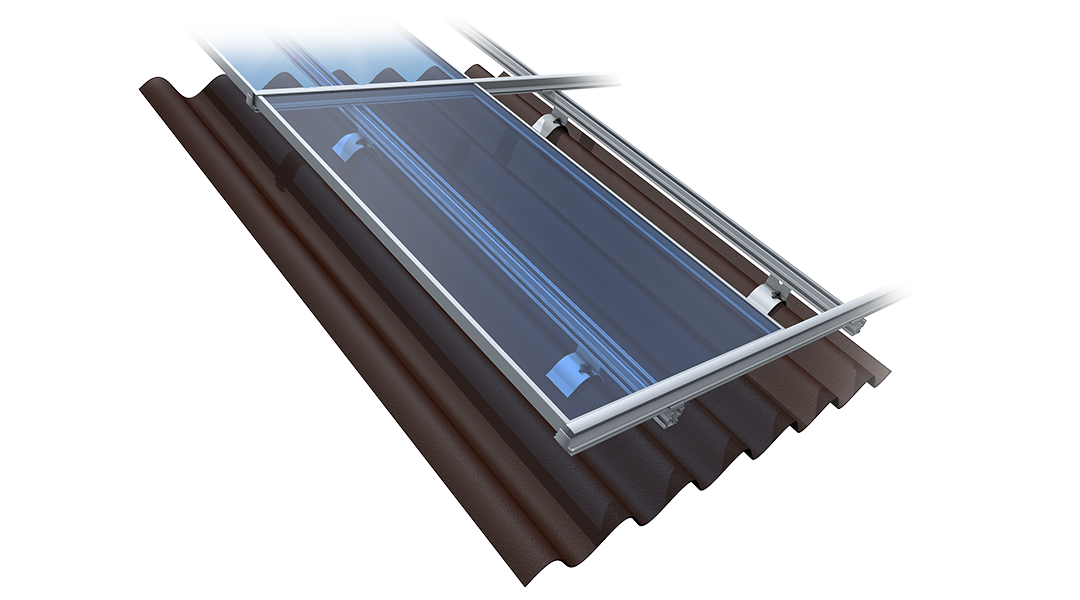

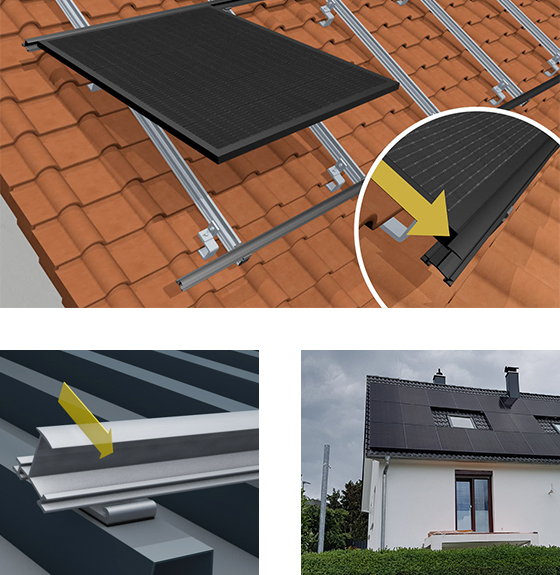

With the smart and high-quality TRI-STAND insertion systems for on-roof mounting, you can realize your projects in an unbeatable short time. Thanks to smart planning software, fewer components and patented SafeClick mounting, the systems are installed extremely quickly, safely and easily on a wide variety of pitched roofs.

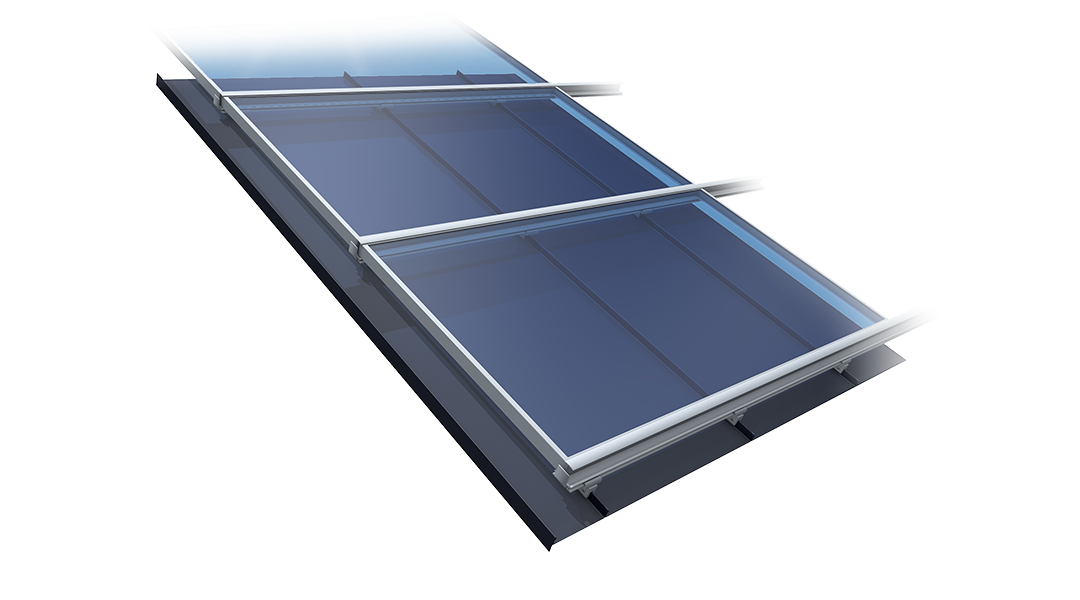

The floating mounting gives no chance for damage due to thermal expansion to the roof, mounting system and module and also ensures a visually closed and aesthetic module field, as no thermal separation is necessary.

TRI-STAND Mounting systems use identical components for upright and transverse mounting and are suitable for all common framed module types. The PV modules are easily inserted into the insertion profiles and are securely positioned due to their own weight. Additional fastening of the modules is completely unnecessary.

You already have a current project? You can sendus your project enquiryhere.

The TRI-STAND assembly system in use

Get an impression of the simple assembly and the few components of the TRI-STAND mounting system.

FAQs about the TRI-STAND mounting system

References

In the following you can see references for photovoltaic installation with TRI-STAND.

Downloads

All information about the TRI-STAND mounting system for download as PDF.