Reach your goal faster with the PV insertion system from TRITEC

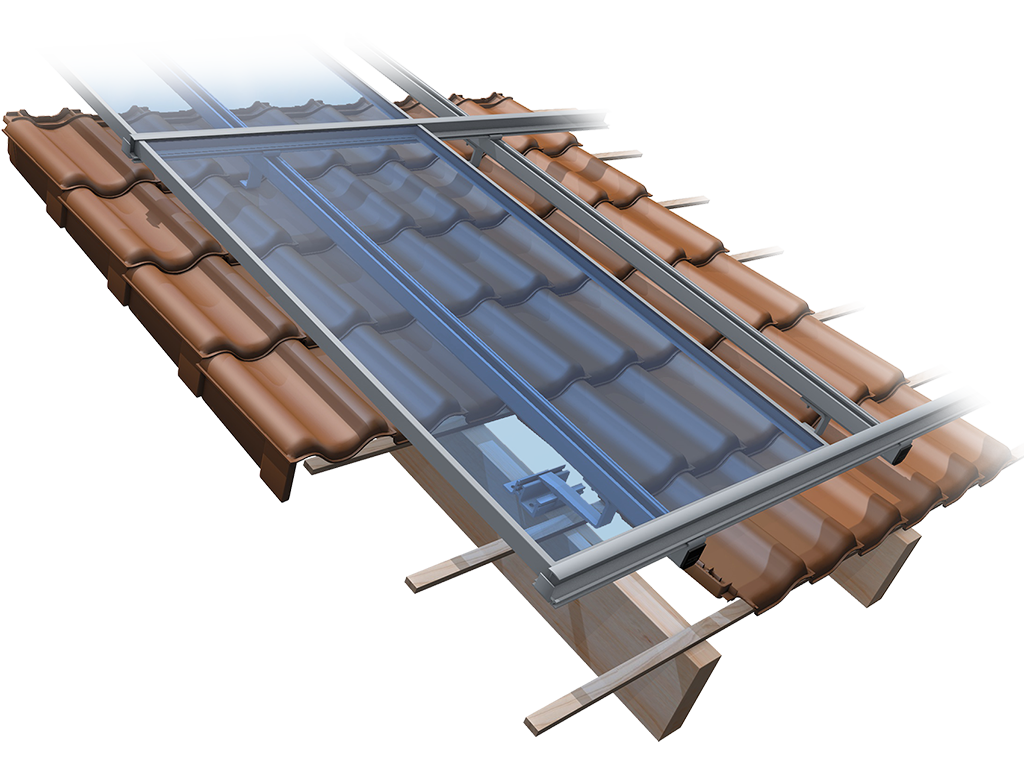

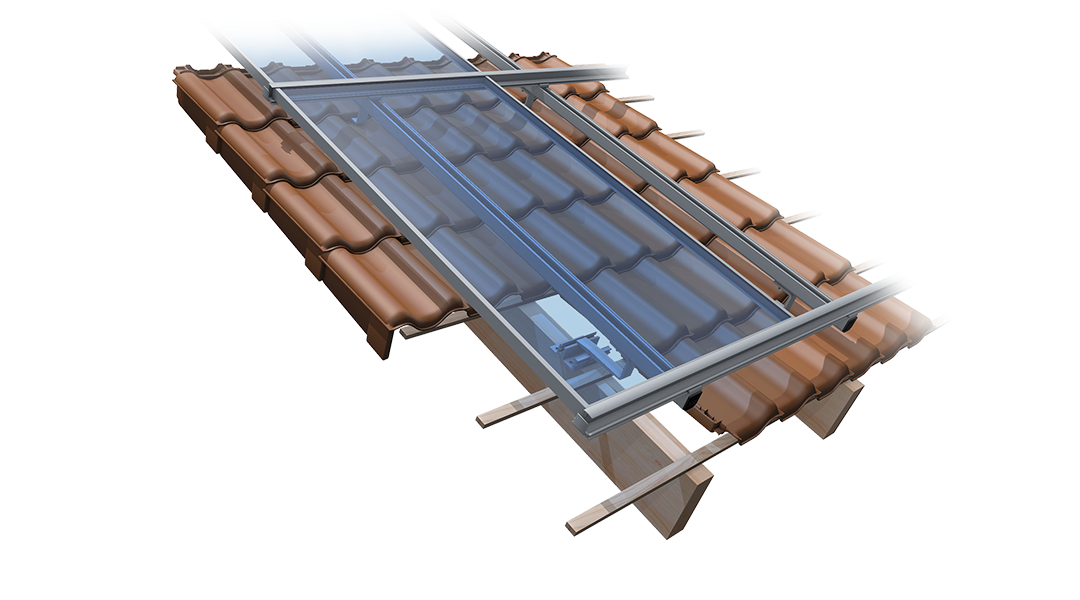

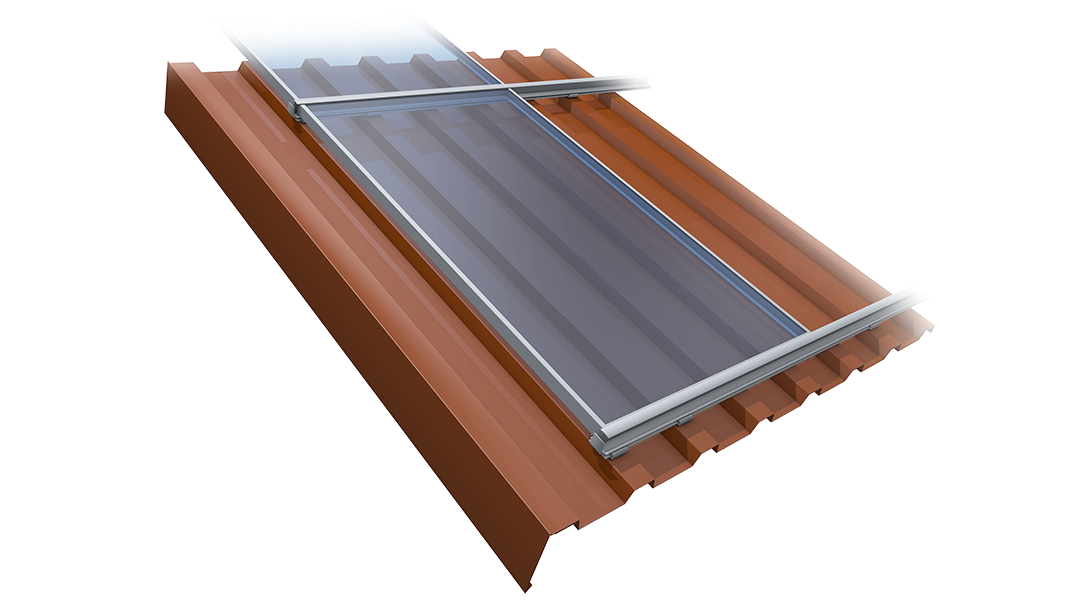

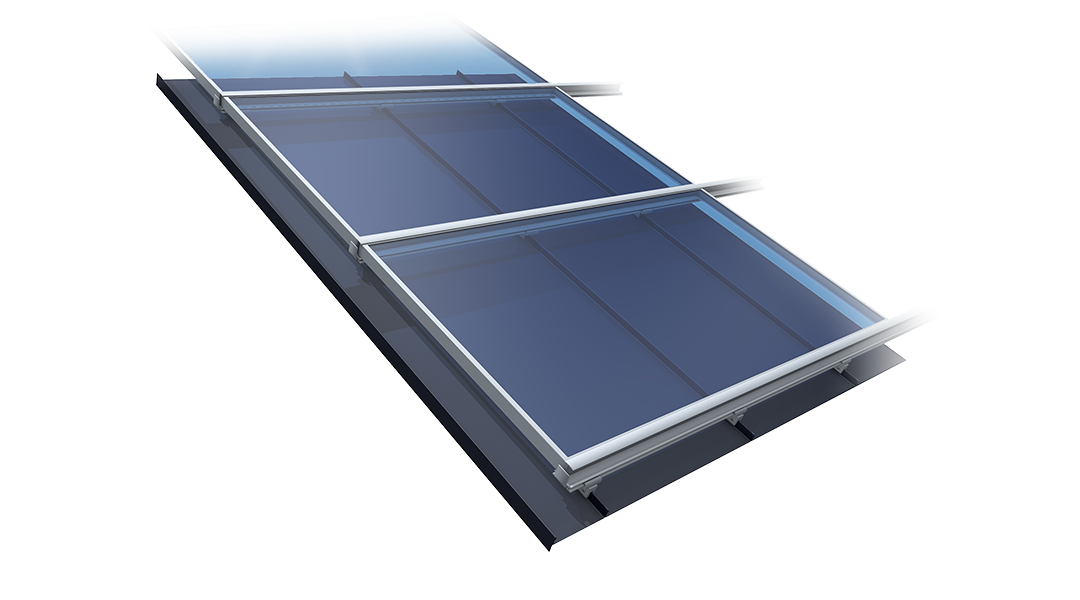

The sophisticated PV insertion system from TRITEC is suitable for the installation of solar systems on all types of pitched roofs, such as gable roofs, hip roofs, mansard roofs and monopitch roofs. In addition, photovoltaic mounting on façades is possible. Well-founded know-how and years of practical experience are the basis for the development of the insertion system. The mounting system offers a solution for almost any roof covering - both for standard installations and for special requirements.

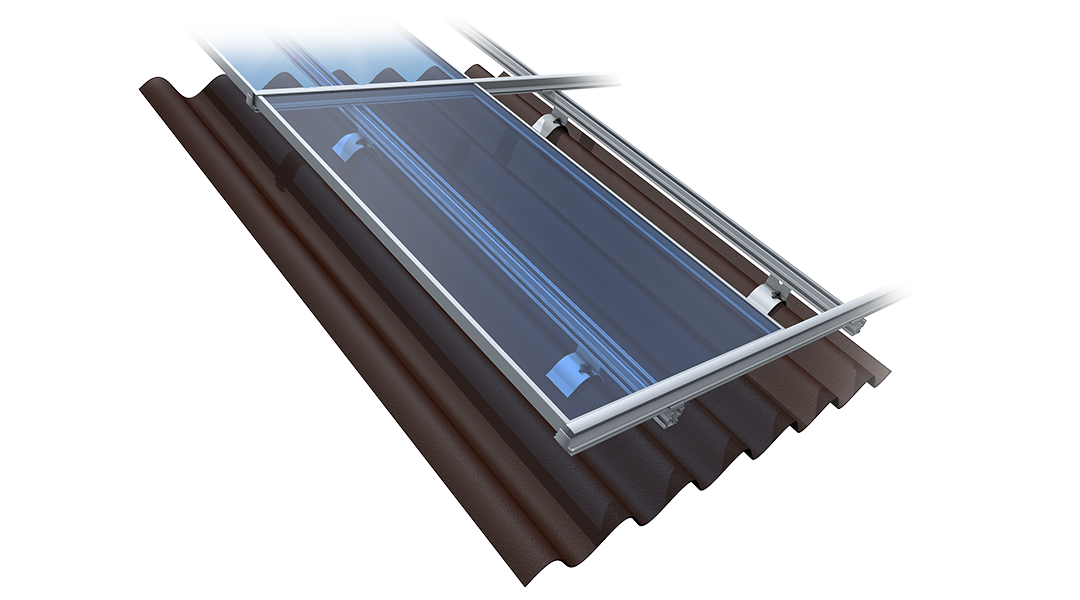

The insertion system was developed for the use of all solar modules from different manufacturers. The solar modules are inserted into the aluminium profile and held in place by their own weight and by friction. Therefore, there is no need to clamp the modules and thus enables a closed module field without clamping distances.

You already have a current project? You can sendus your project enquiryhere.

Areas of application of the photovoltaic insertion system

With the PV aluminum insertion system TRI-STAND we have created a mounting system that makes photovoltaic installation much easier. You simply insert the solar modules here instead of fixing each module separately with module clamps. This has several advantages. Installation is much faster, modules can be easily replaced and thermal expansion is not a problem due to the floating mounting. The system is suitable for photovoltaic mounting on roofs with different roof coverings.

FAQs about the TRI-STAND mounting system

References

In the following you can see references for photovoltaic installation with TRI-STAND.